This is a retro post, so no dated entries…

Davey Jones is a complete experiment in controlled corrosion of metals (and a few other techniques)… The time gage started its life as a Invicta skeleton (not sure which model #) that I bought especially to play around with. I like the quality of its movement and the solid build of the case, but esthetically it had a long ways to go before it could be worn on the wrist…

I really do like the factory engravings on this movement; they are dense and very decorative. The quality control in the Chinese plant where these movements are produced is hit or miss… the engravings can be shallow and uneven at times, but this one was a hit with even, crisp lows. The stainless case rocks! It’s solid quality, but the fake screws on the bezel and lugs are a complete turnoff for me.

In-house movement modifications

The movement was first up for modification. It got disassembled and cleaned. The main plate and all the bridges were oxidized using a brass blackening solution, with special care being taken not to affect the sections where plates and bridges came into contact with wheels, gears or springs. Once the surface area was completely oxidized to black, I used 2000 grit sandpaper to sand the oxidation off most of the parts, leaving the flat surfaces a brushed brass while the engraved pattern remained black. I really like this decorative effect, and have used it several times since this successful experiment. I also practiced my flame painting skills on most of the steel parts of the movement, coating them in a wide, colorful spectrum of surface oxidation.

I decided to install a different set of hands, modified through linear brushing and by pigmenting the white lume to a turquoise blue. The hour wheel on Unital 6497 movements, and its clones (which is what this movement is) relies on the fit between the minutes hand and the cannon pinion for retention, and to allow for less friction between the hour wheel and the minute hand, a very thin washer is used as a bearing spacer. I decided to replace the factory washer (which is small enough to be covered by the minute hand) with a modified time train wheel. I like the extra decoration…

Given the corrosive effect I was trying to achieve, the brushed surfaces of the plates and bridges were left bare brass as to allow them to ever so slowly patina with time…

Casework

After wearing this time gage for a while, I decided to modify the case as well. It was disassembled, and all 3 parts of the case were subjected to some serious burring, then the burring subjected to electro-etching to soften up the effect. I attempted some geneva striping on the caseback, and although the milling machine I use is not solid enough for perfect work, the result turned out to pleasantly match the overall rough motife of the rest of the case.

Bezel

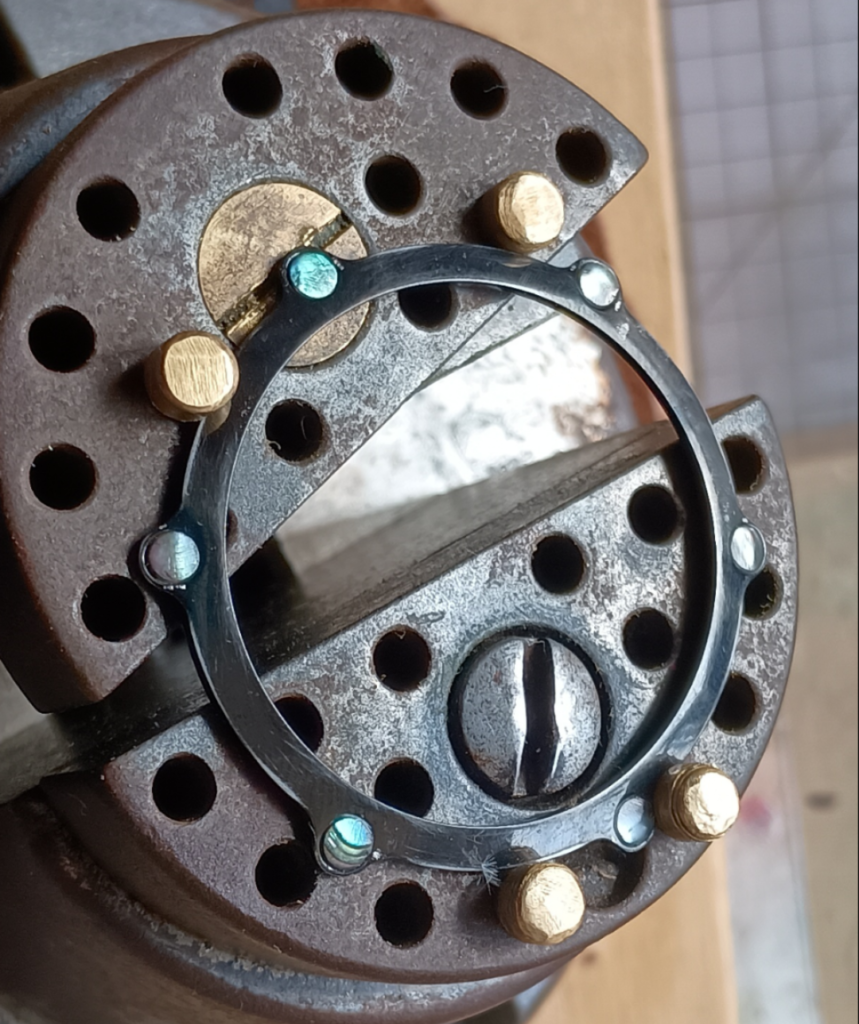

I took the time to modify the decorative bezel around the crystal as well… The fake screws were replaced with hand picked, shaped and polished abalone disks whose color matches the turquoise hands. I also electro-etched the GPF logo into the bezel at 12 o’clock while keeping the rest the original polished black. The photo on the right shows the bezel prepped for electro-etching vinyl tape and nail polish being used as masks…

Maybe Finished?

I think that the resulting gage turned out spectacularly well (given my limited experience), especially after adding some more electro-etched details to the case back and crown.

Upon seeing a wrist shot of CC #4 (Controlled Corrosion #4) on a watch forum, a long time fan of my work commented that it looked like something that had been stuck at the bottom of the ocean for an eternity, and so CC #4 got the nickname “Davie Jones”…